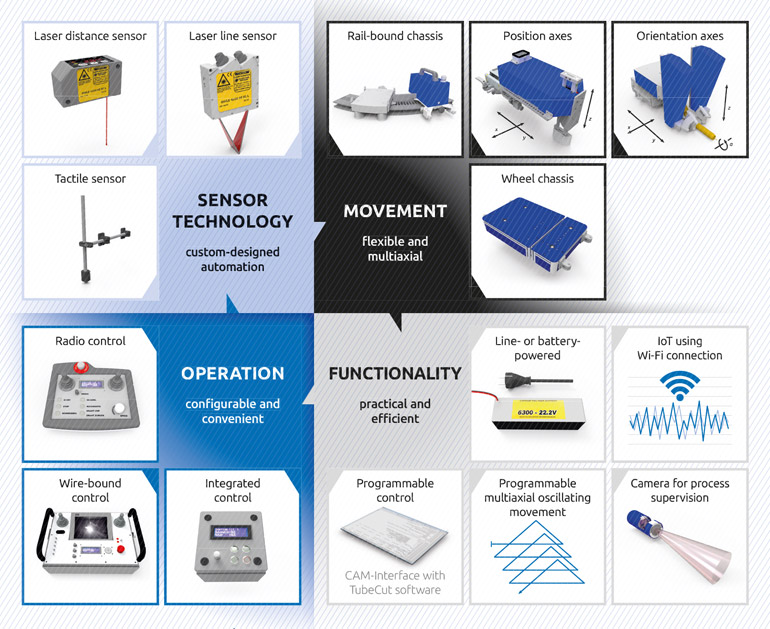

Automation of cutting and welding applications.

With the modular system kit by ZIS!

Any questions? We will be happy to help you!

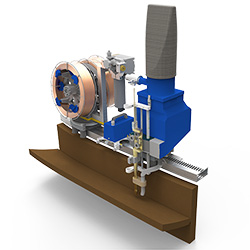

A welding robot that looks like a welding tractor

The intelligent automation of welding and cutting tasks

The cost-efficient solution for the automation of cutting and welding applications. The components can be combined according to the requirements. The extensive module selection allows the configuration of cost-effective and economic solutions. The flexibility of the system and the easy operation enable a fast integration into existing processes and configurations.

Benefits

- Custom-designed configuration with different modules

- Increased automation through flexible sensor integration

- Cost-effective and efficient application

Supported technologies

The multitude of supported cutting and welding technologies and the modular concept of the system make the automation of different production tasks possible. A level of automation comparable to expensive robot applications can be achieved with significantly lower investment.

- Increased quality and process stability

- Increased efficiency

- Improvement of the working conditions

- Cost-effective solution

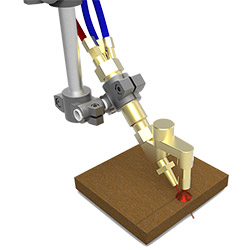

Example 1:

Oxyfuel cutting of 3D-contours

- Integration of magnetic valves for the gas supply

- Laser distance sensors to regulate the vertical and horizontal positioning

- Radio controlled

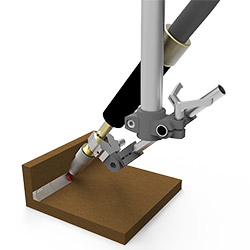

Example 2:

Metal arc welding of block shear connectors

- Two torch holders

- Interface to two welding machines

- Integrated control with end crater filling

- Limit switch for beginning and end of the welding seam with automated return function